Simple Details That Make Perfect Sense

Unlock Your Edge

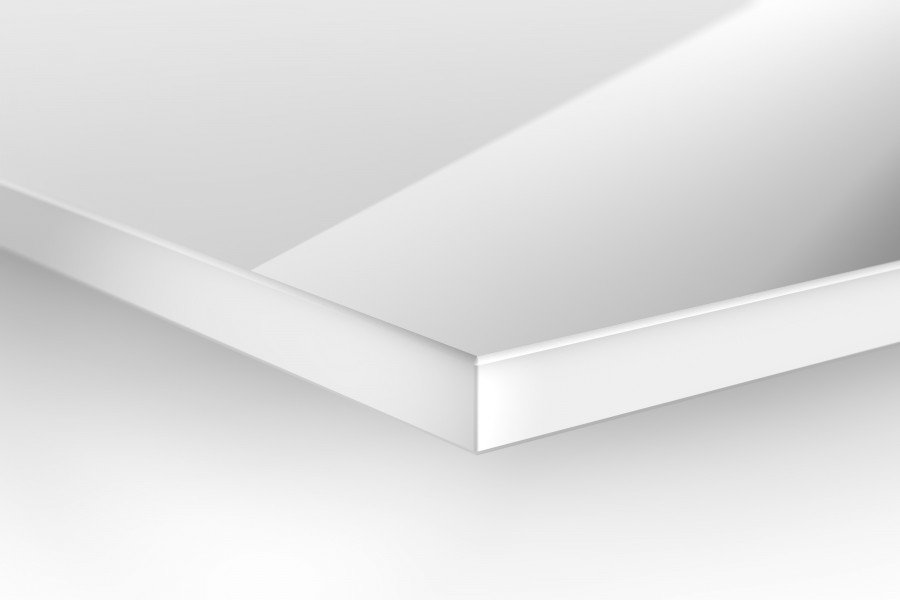

Edgebanding creates a seamless invisible join across the exposed edges of your cabinetry. Laser Technology proves to be a high quality solution packed with functionality and long-lasting enjoyment. Manufactured with high quality materials and superior technology, this application ensures that your edges are scratch resistant, durable and cleanable surfaces.

On-top of these outstanding qualities, the efficiency in assembling this product makes this the most attractive solution for all furniture manufacturers. Laser Edgebanding is a regulated process, to ensure the performance of the product. The finished product must blend well with exisiting materials and meet the expectations of high-volume furniture producers.

How Laser Edgebanding can elevate your project:

- Performs well in Australian and New Zealand kitchens, bathrooms, home offices and shop fittings

- Enhance leading industry trends (high gloss and textured panels) without a framing effect

- No glue joint to collect dirt, chip away or discolour over time

- Heat and moisture resistant

- Creates a bond equal or greater than PUR (no delamination)

- A higher quality finish of edgebanding allows you to promote higher-end finished product at a premium

- Customisable in both colour and finish; smart-look glass, textured laminate, porous finishes and many more

On-top of these outstanding qualities, the efficiency in assembling this product makes this the most attractive solution for all furniture manufacturers. Laser Edgebanding is a regulated process, to ensure the performance of the product. The finished product must blend well with exisiting materials and meet the expectations of high-volume furniture producers.

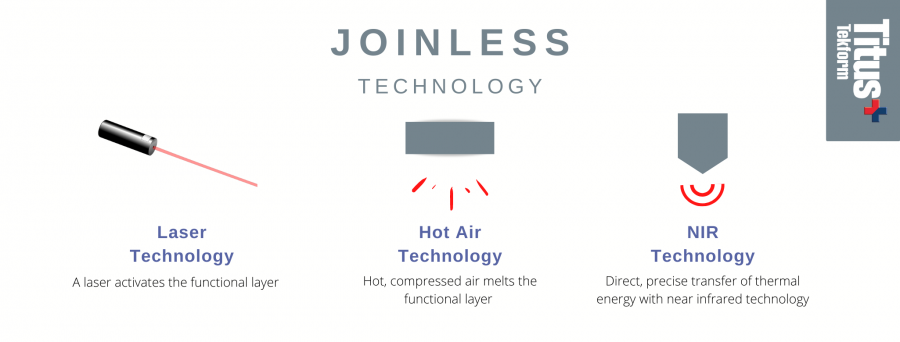

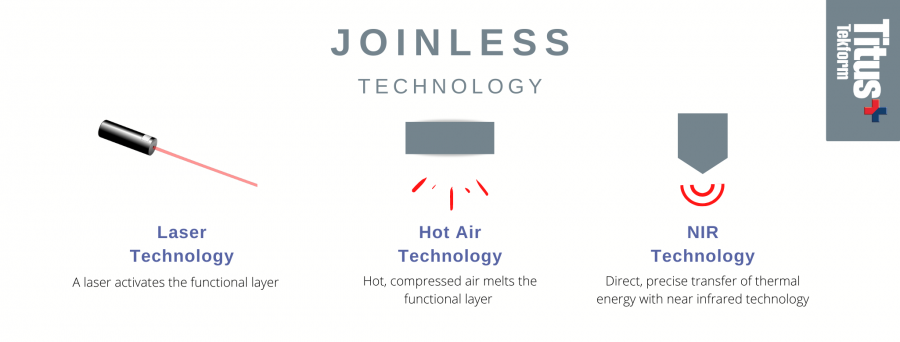

A Break Down of Laser Technology

"This process is rigorous and precise, to ensure you get a seamless edge, every time"

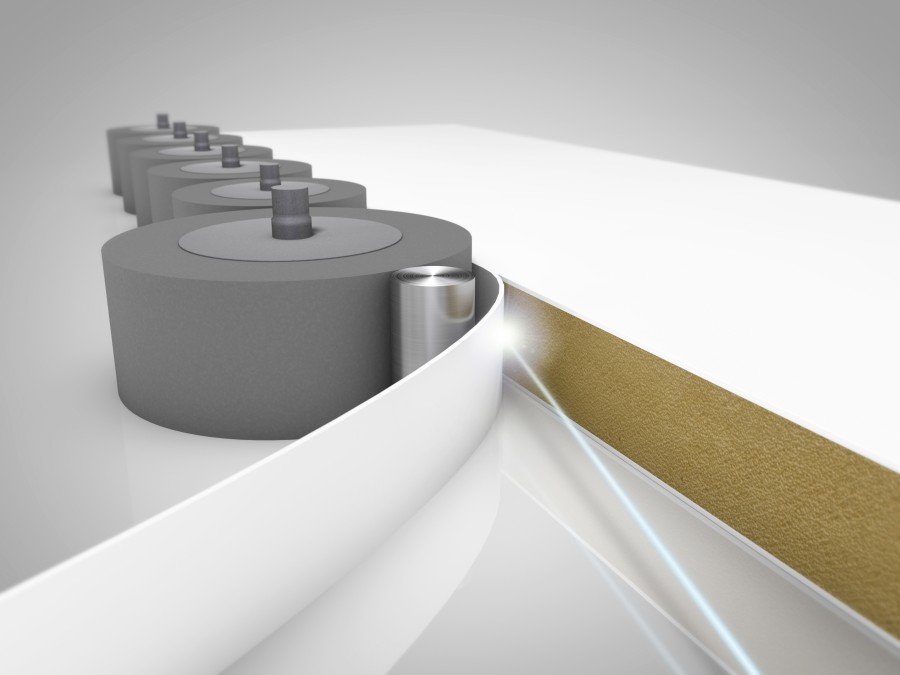

Edgebanding application continues to expand with the introduction of Laser Technology. Traditionally, edgebanding is usually applied with a mechanical roller. The roller fuses the band and primer to the exposed cabinet edge to ensure they stay together. Whereas, Laser Technology applies edgebanding with a perfect invisible join through various technological advancements. Implementing a laser activates the functional layer. Hot, compressed air, melts the functional layer. With a precise transfer of thermal energy which uses Near Infrared Technology (NIR). This process is rigorous and precise, to ensure you get a seamless edge, every single time.

For more information on Laser Edgebanding Technology please speak to your Technical Sales Representative.

Disclaimer: All images in this article have been supplied by REHAU, unless otherwise stated.

Submit your feedback

We are continually finding new ways to fulfil our fit-for-purpose promise and as manufacturer-distributors, we take your product feedback seriously.